Helping the Metallurgical Industry Go Green with Science and Technology

Yunnan province is rich in non-ferrous metals. However, the non-ferrous metal industry has been highly energy- and water-intensive, producing huge amounts of pollution over a long period of time due to the great difficulty in processing those metals and the technical limitations in selecting and smelting them. The State Key Laboratory of Clean Utilization in Complex Non-ferrous Metal Resources jointly built by the Ministry and the Province of KUST (hereafter referred to as the State Key Laboratory) specializes in studying metallurgical furnaces, aiming to achieve energy conservation, emission reduction, and efficiency improvements in the metallurgical industry through various technological means.

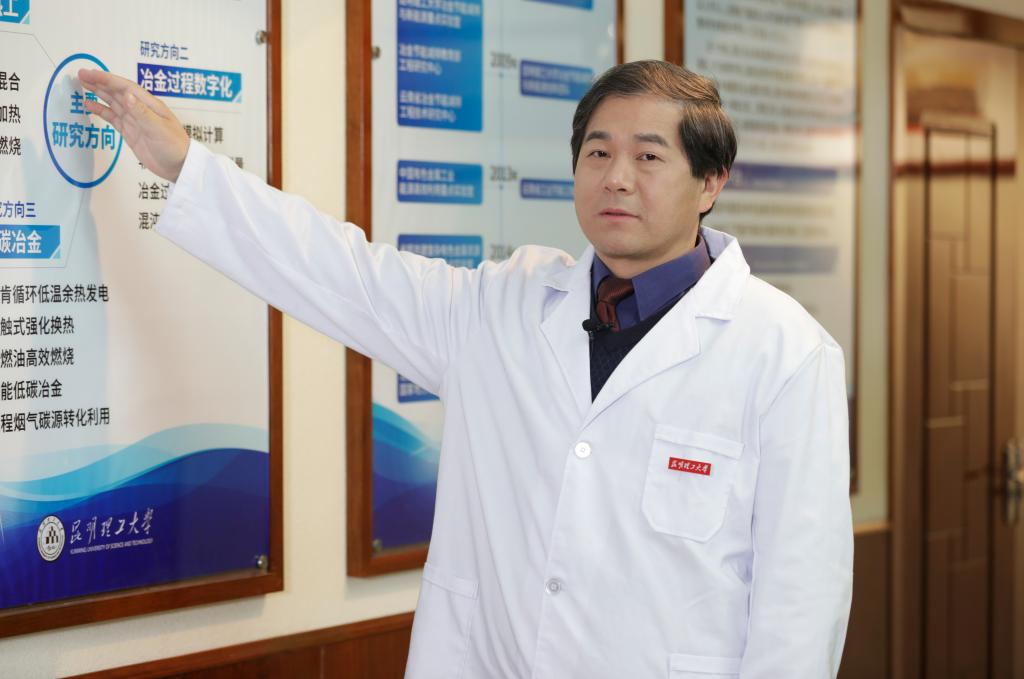

The State Key Laboratory, formerly known as the Metallurgical Thermal Energy Engineering Laboratory, was founded by Professor Cai Qiaofang, former president of KUST in 1985. In 1996, Doctor Wang Hua took over the laboratory at the young age of thirty, and led his team to start the second round of innovation. By integrating thermal-energy engineering with metallurgical engineering, the team carried out basic research and innovation in engineering technology in the fields of thermal-process intensification, energy conservation, and carbon reduction in metallurgical furnaces. Three distinctive research directions were formed through their efforts, including thermal-energy engineering of metallurgical furnaces, digitisation of the metallurgical process, and low-carbon metallurgy.

Having been committed to over thirty years of scientific research in Yunnan province, Professor Wang has led the laboratory team to achieve many theoretical breakthroughs and technological innovations. He has won the National Innovation Pioneer Award, one first prize and one second prize of the State Science and Technology Progress Award, and many provincial and ministerial awards. Notably, the project that privileged him to the first prize of the State Science and Technology Progress Award in 2012 was the “Key Technologies and Application of the Efficient Utilization of Complex Nickel and Cobalt Resources”. The project achieved a major innovation in process-technology integration, offering a solution to the global problem of separating copper and nickel and smelting complex nickel ore with rich magnesium oxide. The innovation can influence the global pricing of such resources and provide a new approach to the energy-saving, clean and efficient utilization of the resources.

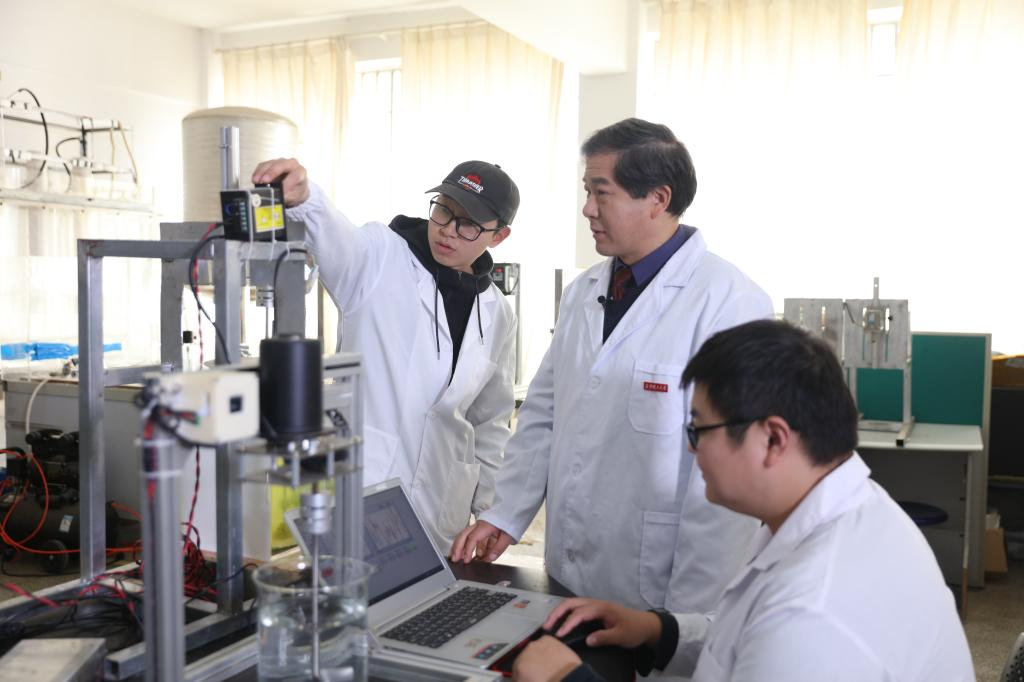

The laboratory team has also made other major innovations. They built a series of mathematical models for the intensified heating for metallurgical furnaces with minimum fuel consumption, prompting the development of the thermal theory of metallurgical furnaces. They developed the technologies of turbulent, swirl-flow-intensified heating for metallurgy furnaces and the techniques of uniform and precise heating for furnaces. In so doing they broke the core technical barrier of lance for smelting furnaces and the dominance of the developed countries in uniform and precise heating technology for high-end metal materials. All these endeavors have made significant contributions to the field of thermal-process intensification in metallurgical furnaces as well as the field of energy conservation both at home and abroad.

In terms of the transformation of scientific and technological achievements, multiple technologies have been applied widely to smelting enterprises and metal-heat-treatment enterprises, which have significantly improved the energy conservation and efficiency of heating furnaces. Hundreds of millions of direct economic benefits have been achieved due to energy saving, emission reduction, and metal-loss reduction. One achievement, the new smelting technology of three-furnace linkage, with independent intellectual property rights, has been widely applied in Jinchuan Group. In the past three years, Jinchuan Group has used the technology to handle 4.56 million tonnes of complex nickel and cobalt raw materials, registering a cumulative added sales of 135 billion yuan. The key technologies such as intensified heating for metallurgical furnaces have been applied to companies like Aluminum Corporation of China and Jingchuan Group, resulting in an increase of 72.81 billion yuan in added sales in the recent three years. Some of the technologies have been exported to twenty-one countries including the United States, Germany, Japan, Argentina, Peru, etc., promoting the internationalization of China's metallurgical furnaces. The overall technology has reached the international leading level.

The laboratory team is also the innovative team of metallurgical energy conservation and emission reduction at KUST. Oriented towards the major national strategy and industrial development needs, it has worked with universities renowned for their metallurgical engineering discipline, scientific research institutions, and large-scale enterprises to conduct industry-university-research cooperation. The team has produced a large number of major scientific and technological achievements and industrial demonstration projects. Over the years, the team has cultivated nine postdoctoral fellows and three hundred and sixty-nine doctors and postgraduates. It also attaches great importance to students’ practical training and the students have won awards in various national contests including the National University Student Social Practice and Science Contest on Energy Saving & Emission Reduction, and the National University Student Metallurgical Science and Technology Competition.

During the 14th Five-Year Plan period, the State Key Laboratory will focus on the 14th Five-Year Plan and Vision 2035 of Yunnan Province, take the development path driven by scientific innovation, aim for energy saving and emission reduction in the metallurgical industry, and carry out key scientific and technological projects to realize the breakthroughs in the field. The State Key Laboratory will strengthen its construction and endeavor to advance the green and low-carbon development of the metallurgical industry in Yunnan province.

Translated by: ZHANG Xiao, Faculty of Foreign Languages and Cultures

Edited by: MA Lifei, Faculty of Foreign Languages and Cultures (English)

Source: KUST’s Innovation Team of Metallurgical Energy Conservation and Emission Reduction

Issued by: Division of International Cooperation (English)

Edited by: KUST News Center (Chinese)